Your Option

We’re on a mission to revolutionize packaging with innovative and practical eco-friendly solutions.

With our own production hubs and extensive networks, we provide flexible supply chain solutions, ensuring your needs are met swiftly and sustainably.

Latest News

Our Purpose

We’re committed to spearheading sustainability through Green-Tech and innovative approaches. By crafting water-soluble, compostable, and biodegradable solutions, we uphold our mission to promote sustainability while ensuring practicality for daily needs.

Water-Soluble

Effortlessly dissolves in water, leaving no harmful residues behind

Environmentally Safe

Tested to be non-toxic, doesn’t contain PP, PE, PS, PVC plastic

Patented-Technology

Backed by patented technology, guarantee unique and effective sustainability

Certification

EzyGreenPak water-soluble bags are certified through REACH Substances of Very High Concern (SVHC) Testing & Environmental Ink Test, ensuring that both the material and ink are free from harmful chemicals that pose risks to human health and the environment

PVA is FDA-approved for food packaging, ensuring safety

The China National Accreditation Service for Conformity Assessment (CNAS) irritation test demonstrate that EzyGreenPak bags do not cause irritation to skin, mucosal, or ocular tissues

Results from NTSQP testing align with ISO 14851, indicating that over 90% of EzyGreenPak’s water-soluble materials biodegrade within 72 days.

Testing by the China National Center for Quality and Supervision of Plastics (NTSQP) reveals that over 90% of EzyGreenPak’s water-soluble materials biodegrade within 72 days, meeting ISO 14851 standards.

NTEK environmental ink test confirms that the inks used in EzyGreenPak bags do not hinder plant growth or cause environmental pollution.

The material has successfully met the required standards for the formaldehyde test, with certification and verification provided by CIRS.

Water-Soluble

Case Study

To discover real-life examples showcasing the positive impact of our eco-friendly solutions on businesses like yours.

Contact us for more information.

Customise Your Own Style

Utilize our production hubs to personalize your branding with custom designs. Feel free to innovate with our materials and create new packaging products beyond bags. We’re enthusiastic about collaborating on your packaging projects. By offering your customers water-soluble, plastic-free, and non-toxic options, you empower them to reduce plastic waste.

CO₂ we avoided*

trees we saved*

EzyGreenPak replaced plastic packaging

*To learn how we calculate the carbon emission, please click here

Listen to what our customers have to say about our services

Smoooth Biz Limited

The water-soluble bag aligns perfectly with our concerns about ESG issues and its water-soluble nature helps us leave a lasting impression on our customers.

Flashgreen

Ever since we transitioned to EzyGreenPak's water-soluble bags, our store has experienced a notable positive shift in environmental sustainability. These bags have not only left a lasting impression on our company but also garnered a strong reputation. Our customers particularly appreciate the eco-friendly nature of these bags.

Frequently asked questions

EzyGreenPak is composed of Polyvinyl Alcohol (PVA or PVOH) and water. PVA is a synthetic polymer known for its water-soluble and biodegradable properties. Unlike conventional plastics such as PP and PE, which are water-insoluble and not easily biodegradable, PVA contains hydroxyl groups that make it hydrophilic, allowing it to dissolve in water. Microorganisms in soil or water can break down PVA into carbon dioxide, water, and biomass, contributing to its biodegradability.

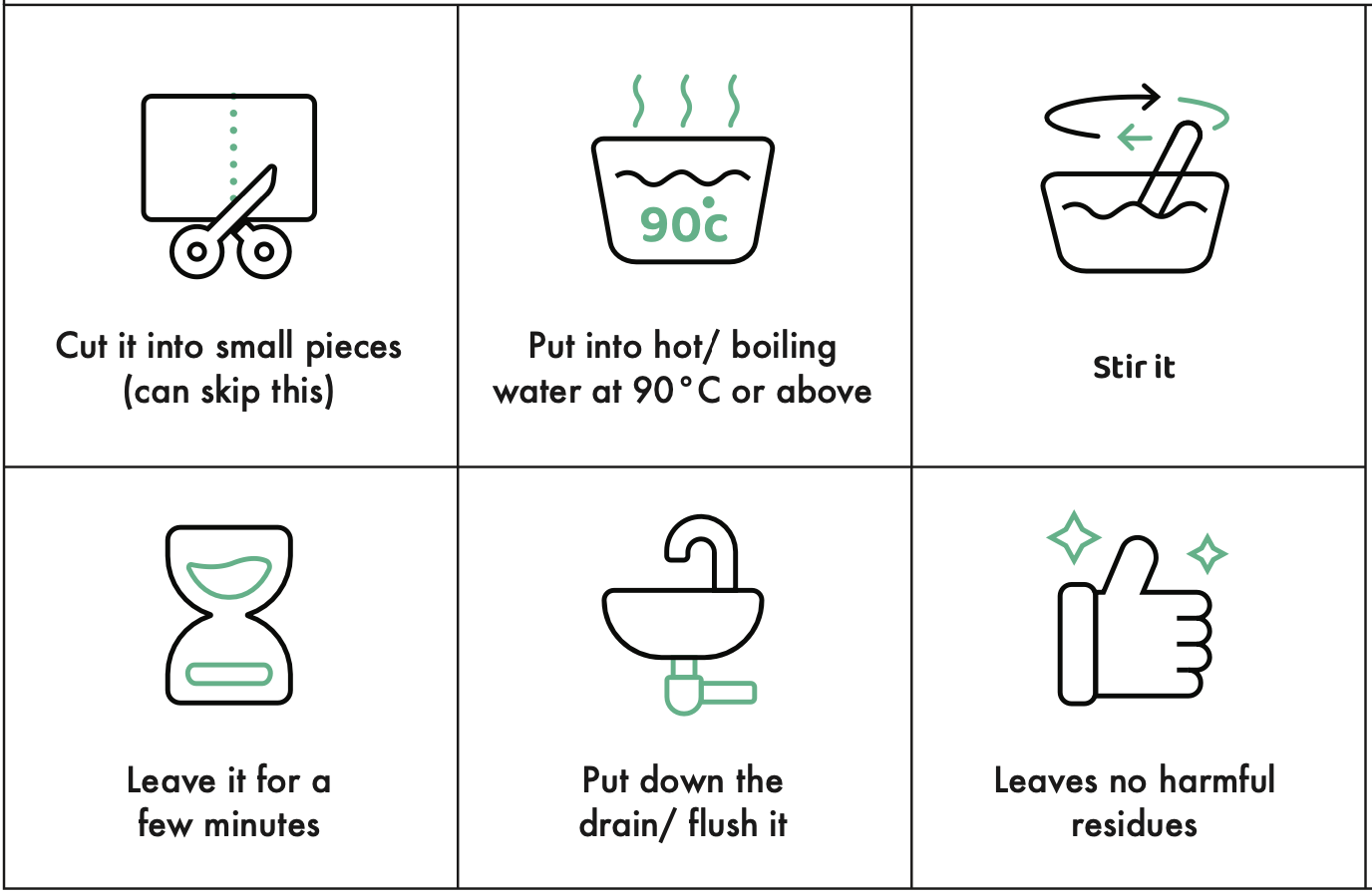

We suggest dissolving it in water that is heated to 90°C or higher. Place the bag in a container and pour boiling water over it. Within a few minutes, it will dissolve. After dissolution, you can safely dispose of the remaining liquid down the drain. Wastewater treatment at a sewage plant will handle the breakdown of the dissolved material by microorganisms, resulting in the production of only carbon dioxide and water, without any microplastics formed.

EzyGreenPak has undergone SGS lab testing and testing by the China National Center for Quality and Supervision of Plastics (NTSQP), confirming that our products are free from PP, PE, PS, and PVA plastics. Additionally, these tests have shown that over 90% of our materials biodegrade within 72 days.

The residue that remains is a result of the time it takes for the PVOH material to undergo hydrolysis. Simply put, these residues are not microplastics, so there is no need for concern. The PVOH polymers will break down into smaller individual molecules, lacking a physical solid structure, unlike microplastics. The dissolved PVOH will then react with microorganisms, ultimately transforming into harmless CO2 and water.

![EzyGreenPak水溶環保袋破塑膠困局 [星島日報]](https://ezygreenpak.com/wp-content/uploads/2025/04/CleanShot-2025-04-26-at-16.14.20-150x150.png)